Unlocking the Secrets to Efficient Lift Repairs: Specialist Insights Exposed

In the world of lift fixing and upkeep, revealing the techniques that bring about effective and efficient solution is comparable to deciphering a complex problem. Specialist insights function as the guiding light via the maze of difficulties faced by upkeep experts in the vertical transport sector. By delving into the midsts of positive strategies, repairing methods, and the continuous search of ability enhancement, the course to raising upkeep requirements reveals itself. As we start this trip to demystify the keys behind streamlined lift repairs, a globe of possibilities arises, promising a future where downtime is decreased, security is prioritized, and functional quality ends up being the norm.

Common Lift Repair Service Obstacles

An additional widespread difficulty in lift repair services is the lack of proper maintenance documents. Without precise maintenance records, fixing professionals might have a hard time to diagnose issues effectively or prepare for prospective issues. This can result in longer fixing times and raised expenses as specialists work to repair problems without historical data to lead them.

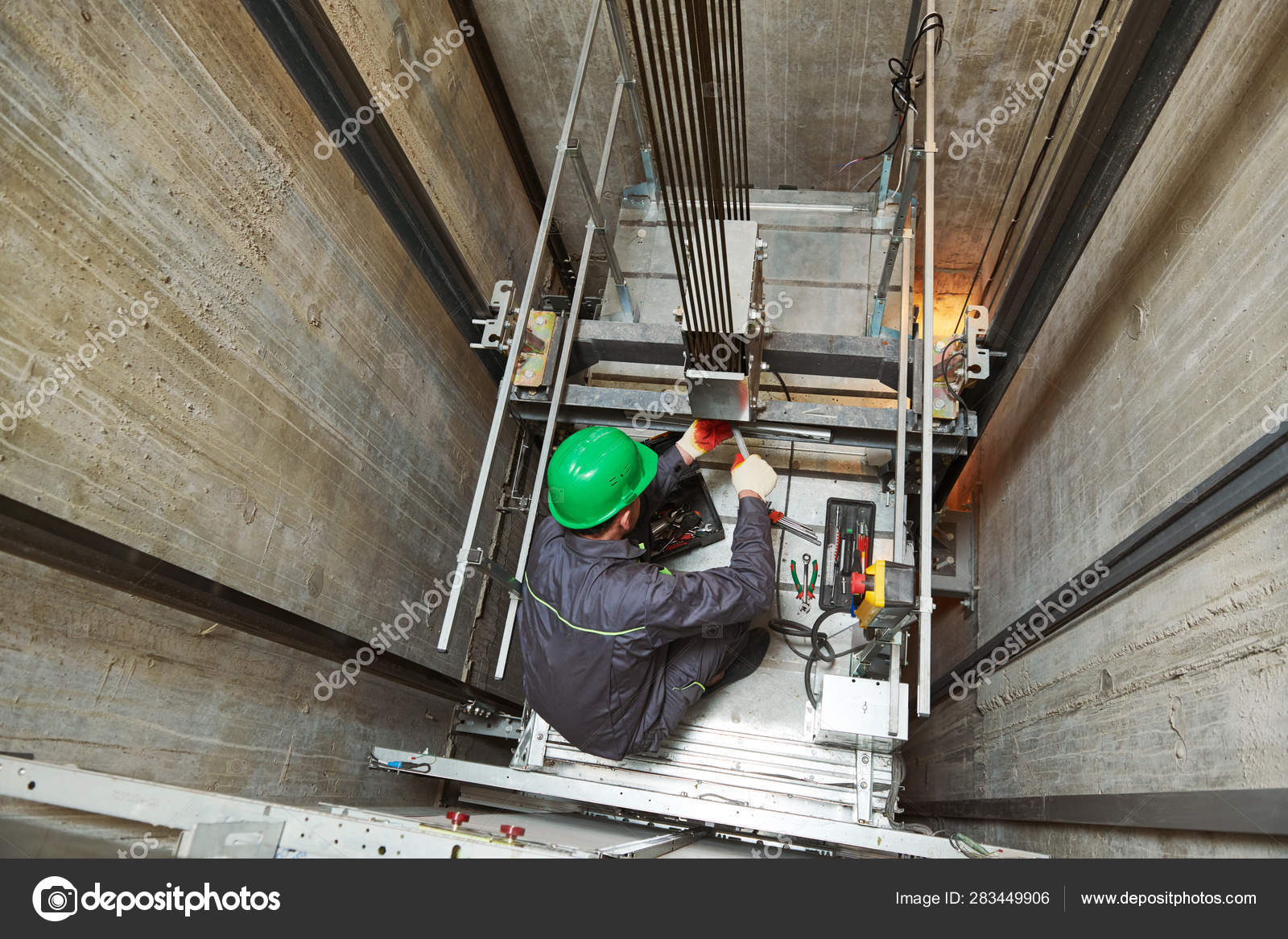

Moreover, ease of access concerns within lift shafts can posture considerable difficulties throughout repair services. Restricted room, uncomfortable angles, and complex equipment can make it tough for specialists to get to the needed components for fixing work, lengthening the general fixing process - Lift Maintenance Repair. By addressing these typical challenges proactively, lift repair service professionals can boost operational effectiveness and ensure the smooth performance of vertical transportation systems

Proactive Upkeep Techniques

Applying proactive upkeep strategies is vital for ensuring the durability and optimum performance of lift systems. By embracing an aggressive method to upkeep, building managers and lift upkeep groups can address prospective concerns before they intensify right into expensive fixings or downtime. One efficient method is to develop a normal maintenance routine that consists of complete evaluations, lubrication of moving components, and screening of safety functions.

In addition, spending in training programs for upkeep team can boost their abilities in recognizing potential issues and performing preventive maintenance jobs properly - Lift Maintenance Repair. By encouraging upkeep groups with the expertise and devices needed to proactively preserve lift systems, building owners can minimize disturbances, expand the life-span of their lifts, and make sure a trusted and secure vertical transportation experience for occupants

Troubleshooting Strategies

Efficient troubleshooting techniques are necessary for without delay identifying and settling issues with lift systems to decrease downtime and guarantee optimum efficiency. One efficient strategy is to start with a thorough aesthetic examination of the lift elements, examining for any visible indications of wear, damage, or misalignment.

Enhancing Repair Service Skills

Enhancing proficiency in lift system repairs is a basic aspect of guaranteeing optimal functionality and minimizing functional disturbances. Lift specialists need to constantly work on honing their repair abilities to satisfy the needs of modern lift systems.

Furthermore, remaining upgraded with the most recent innovations in lift technology is vital for service technicians looking to improve their repair service abilities. This involves actively looking for info about brand-new elements, software application updates, and maintenance methods to properly identify and remedy concerns. By spending time and initiative right into constant understanding and practical experience, lift technicians can substantially improve their repair competencies and contribute to the efficient performance of lift systems.

Elevating Upkeep Specifications

Raising maintenance requirements in lift systems is critical for making sure prolonged functional effectiveness and safety. Normal upkeep not only boosts the performance of lift systems yet likewise lessens the danger of unanticipated breakdowns and makes certain the safety of individuals. By adhering to strict upkeep protocols, lift proprietors and operators can dramatically minimize the probability of expensive fixings and downtime.

Implementing a comprehensive maintenance timetable that consists of normal assessments, lubrication of moving components, and aggressive substitute of used elements is crucial. Using advanced technologies like IoT sensors and predictive upkeep software can aid in keeping track of the lift's problem in real-time, allowing timely treatments prior to concerns escalate. Additionally, providing continuous training for maintenance team on the current market standards and best methods is necessary for upholding maintenance quality.

Furthermore, cultivating a society of responsibility and focus to information amongst over here maintenance groups can further boost upkeep requirements. Encouraging open communication channels for addressing and reporting upkeep worries promptly can help in preserving a high level of lift system integrity. Inevitably, by raising and focusing on upkeep requirements, lift systems can run efficiently and securely for an extended period.

Final Thought

Finally, effective lift repair work call for positive upkeep approaches, repairing methods, and boosted repair abilities. By raising and addressing common obstacles upkeep requirements, upkeep experts can successfully ensure the smooth operation of lifts - Lift Maintenance Repair. Carrying out these specialist understandings can lead to boosted performance, lowered downtime, and boosted safety and security for both guests and tools

In the realm of lift fixing and upkeep, discovering the techniques that lead to reliable and efficient solution is similar to decoding a complicated problem.One more widespread challenge in lift fixings is the absence of appropriate maintenance records. By embracing a positive strategy to maintenance, building supervisors and lift upkeep teams can attend to prospective problems before they escalate right into pricey repair work or downtime.In conclusion, effective lift fixings require positive upkeep methods, troubleshooting strategies, and enhanced repair skills. By boosting and dealing with usual challenges upkeep criteria, upkeep professionals can successfully make certain the smooth operation of lifts.